What the Light On Means

Interpreting indicator signals and choosing the right action

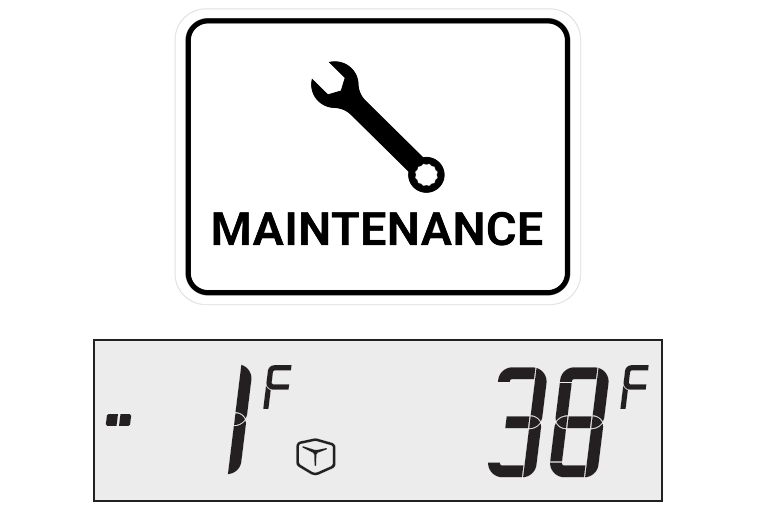

Indicator lights on Sub-Zero panels are a built-in communication system from the manufacturer. A steady or blinking light, along with any accompanying messages on the display, conveys a state of the system, a recommended action, or an error condition. Because Sub-Zero models differ in features and firmware, there isn’t a single universal code interpretation. However, several common patterns recur across many units:

Color: Amber/Yellow often signals a warning or maintenance need, while Red typically indicates a more serious issue. White or blue lights can indicate normal operation or specific informational messages, depending on the model. blink patterns (solid vs blinking) frequently differentiate between temporary alerts and persistent faults. Displayed codes or brief text messages should be cross-checked with the user manual or a service guide for your exact model.

Pattern: A steady light can mean “all good, but something requires attention soon” or a default mode (like defrost in progress). A blinking light usually signals a fault in a subsystem (thermostat, sensor, ice-maker, water system, or control board). A rapid or irregular blink often signals an error that warrants immediate inspection to prevent food spoilage or further damage. When you see a light, take note of the color, whether it’s blinking, and what the display shows—these details speed up diagnosis.

In practice, light indicators guide homeowners to perform a few quick checks before summoning a technician. Look at door seals, check that doors close properly, verify temperatures in both compartments, listen for unusual sounds, and inspect for frost buildup or water leaks. If safe, you can perform basic housekeeping tasks—clean coils, reseat panels, and ensure proper airflow around the unit. If the light remains on or you notice rising temperatures, it’s time to call a professional. Our team in Gilroy specializes in translating these signals into concrete repair plans, using genuine Sub-Zero parts and documented diagnostics.

Understanding your specific model’s indicators is essential. If you’re unsure, take a few photos or a short video of the display and the lights, and have your model number ready when you call. This helps us prepare the right diagnostic steps and parts for a faster, first-visit resolution.

Practical steps you can take now

1) Check the doors: Ensure gaskets seal firmly and doors are fully closed. A poor seal can trigger warnings or reduce cooling efficiency. Clear obstruction around vents to enable free air flow.

2) Verify temperatures: Use a thermometer to confirm that the refrigerator is around 37–40°F (2–4°C) and the freezer around 0°F (-18°C). Significant deviations indicate a cooling issue that needs attention.

3) Inspect for frost or ice buildup: Excess frost can impair airflow and cooling. A light warning may prompt defrost-related servicing or sensor checks.

4) Listen for unusual noises: Squealing, grinding, or loud buzzing can signal failing fans, a worn compressor, or loose components. Early detection saves time and money.

5) Check water and ice components: Leaks, unusual ice formation, or poor ice production can accompany indicator signals. This often points to water inlet issues or defrost system problems.